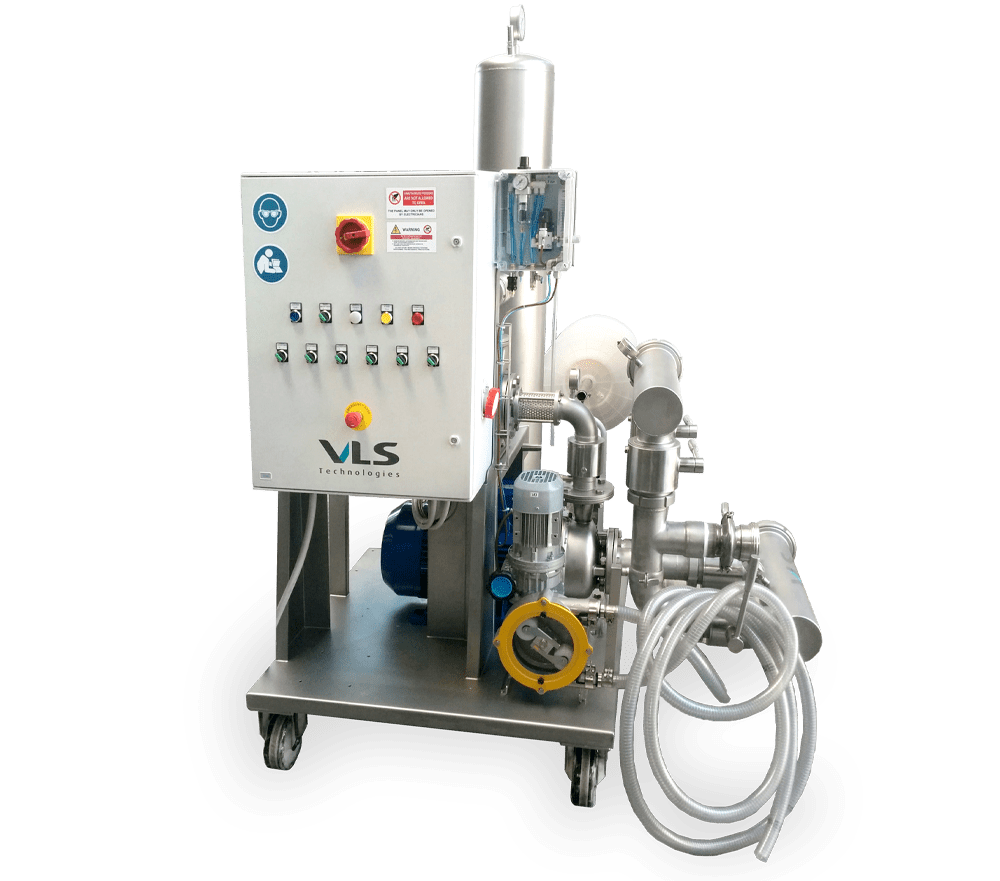

Pressurization unit with batch cycle PFB

Standard version in AISI304 Stainless Steel composed by:

Standard version in AISI 304 Stainless Steel composed by:

Standard version in AISI304 Stainless Steel composed by:

Cantina Montelliana is the most important wine-producing cooperative of the Montello and Colli Asolani area. Cantina Montelliana distinguishes itself for the mix between innovation and tradition in all the steps of the producing process, a frequent characteristic of wine-making establishments with a long history. Nowadays Cantina Montelliana uses our continuous floater and an isobaric cross-flow filter with 24 membranes for the filtration of sparkling wines.

Do you want to get in touch with us? Do not hesitate to write to us, we will be happy to answer your questions. We are at your disposal for any information request and will answer you as soon as possible.